Products

SVR 10/20 (TSR 10/20)

Our factory of SVR10 is equipped with the whole machine line and biofuel dryer imported from Malaysia, where the natural rubber processing technology and method is considered as the most advanced in the region. Due to most of raw materials source of natural rubber in form of cup-lump collected from local suppliers and private rubber plantation that usually have got the poor quality mixed with various foreign matters, organic or inorganic, and unfavorable chemicals.

In order to eliminate completely harmful foreign matters and unfavorable chemicals for the sake of increasing the quality to reach the international quality standard, we have been brave to invite Malayan experts to research the sources of raw materials in localities and basing on the fnding, to have consulted us in choosing out the most favorable technology of processing. Eventually, we have decided to choose the processing technology by Malaysia and imported the whole machine line and biofuel dryer from Malaysia at the cost much bigger than cost of machine line fabricated from local makers in Viet Nam. This is considered as a breakthrough step for the sake of increasing quality of the processed natural rubber and competitive competence by the rubber industry of Vietnam with competitors in the region. In particular, to increase the norms (Po,Pi) of this product, we have studied the method and experience from the advanced countries in field of rubber processing being to apply hanging of unfinished product for some times before drying. This is a new and advanced treatment method, not yet got popular in Viet Nam so far, which has really got success in increasing the norms (Po, Pri) at the expectation. The factory’s current capacity is designed for 4 MTS per hour, approximately 2000MTS per month, for the first stage and this capacity will be increased more intentionally after one year later. Regarding packing, we can shape into bales of 33,33kgs, 35kgs, 50kgs and 110kgs at customer‘s requirement.

SVR 3L

This is a very common in daily life and in manufacturing companies. The important characteristic of SVR 3L rubber is ensuring the content of impurity Po, colour (Lovibond), and dirt within the standard. Currently, this is the most widely used rubber.

The rubber with Po of over 35 has good elasticity and durability. Therefore, it is often used to produce care tires, belts, electric cables, etc.

SVR 10CV60

SVR 10CV60 (constant viscosity) has the constant viscosity and high flexibility. In addition, it has very good adhesion. Therefore, it is widely used in daily life and many different industries.

With its softness and flexibility, it is used in producing elastic strings, glue, the surface of table tennis rackets, etc.

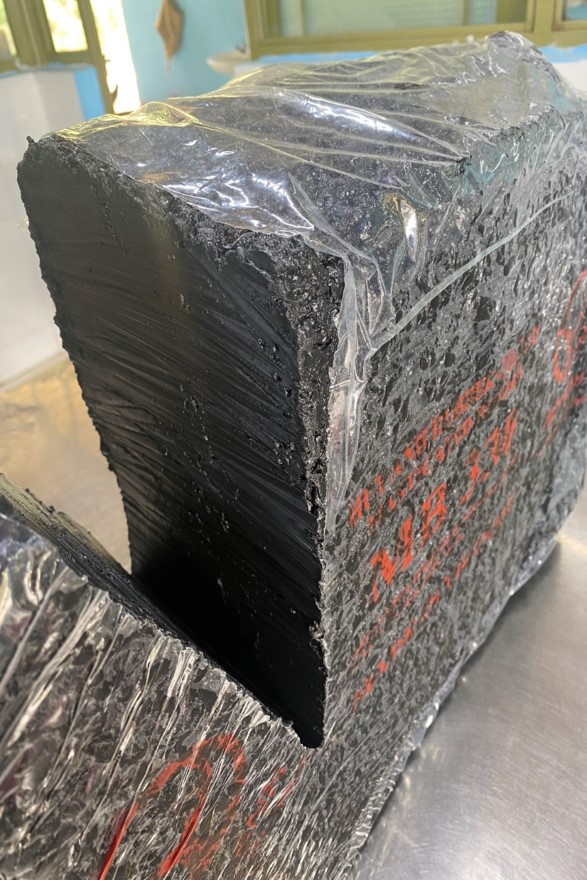

Masticated rubber

Masticated rubber has black carbon. Black carbon has light black colour, good adhesion, the ability of improving durability of rubber. Specifications of the masticated rubber include:

– Color: Light black

– Adhesion improvement: The ability of increasing the adhesion of rubber

– Durability improvement: The ability of improving durability of rubber

– Color creating: Masticated rubber is used to creating blackness for rubber products

– Application: It is used to produce bicycle tires, motorcycle tires, and other industrial products

RSS (RUBBER SMOKE SHEET)

– RSS rubber in general (there are rubber types classified in order from high to low quality: RSS1, RSS2, RSS3, RSS4 and RSS5) or also known as ribbed smoked sheet latex, is made directly from newly harvested natural rubber latex and coagulated. The coagulated rubber sheets are then dried in air or smoked in a furnace, so RSS finished rubber is called smoked sheet latex.

– RSS3 rubber is mostly produced and is the most popular among rubber types from RSS1 to RSS5.

– Application: RSS3 rubber is mostly used to produce tires.